So it started… here… with a maple blank from ebay and headstock templates from the excellent TDPRI forum.

Marking out

The first job on the blank was to get one edge of the blank planed flat and square – this will form the reference for fitting the truss rod and slotting the fretboard.

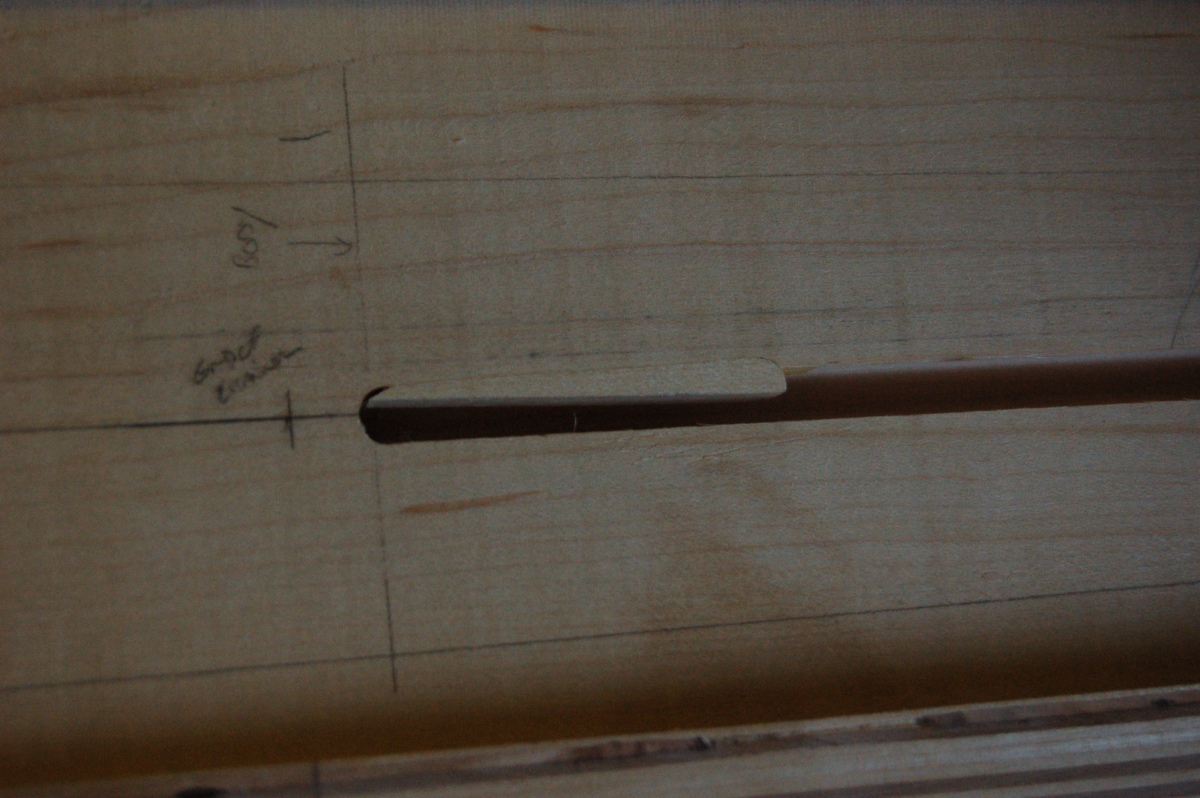

Once one edge is square and straight, I could mark the neck out, including the position of the truss rod.

Truss rod channel

From the Fender drawing, the truss rod channel is formed from two different curves: 255″ radius towards the heel and 115″ radius towards the headstock. I plugged these, and the depth of the channel at the mid-point into Excel to work out the measurments for a couple of curved rails that would vary the depth of cut along the length of the neck as I ran the router over them to cut the truss rod channel.

(Incidentally, I couldn’t get the dimensions on the above drawing to work out – the radius and the 0.715″ dimension seem to be mutually exclusive – the depth of the channel at the 1st fret works out at 0.715″ with the radius/centre depth shown- YMMV)

I didn’t bother making any fancy jigs, just screwed the rails to the neck blank and set about routing the slot:

Cock-up number one – I wasn’t holding the router fence tightly enough against the work on the first pass, and the router pulled off line (I also stopped the channel at the wrong mark – Doh!):

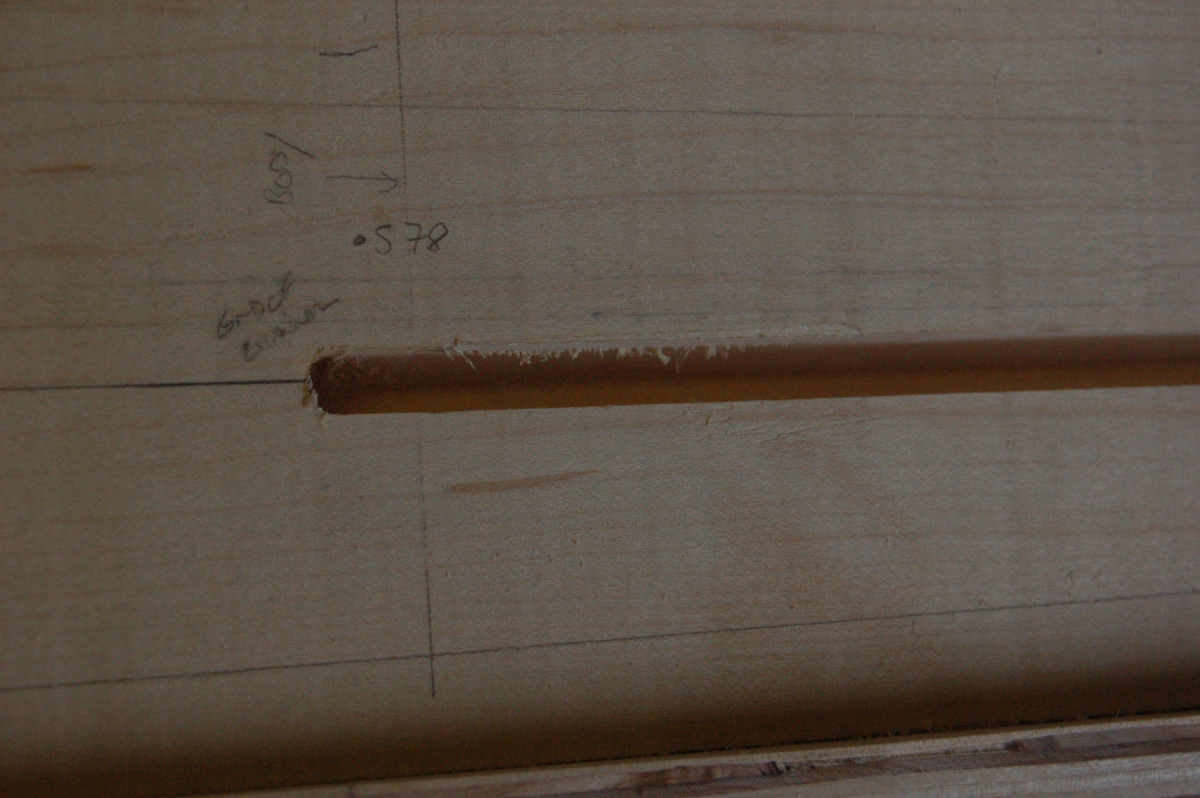

Repair #1:

Fret slots

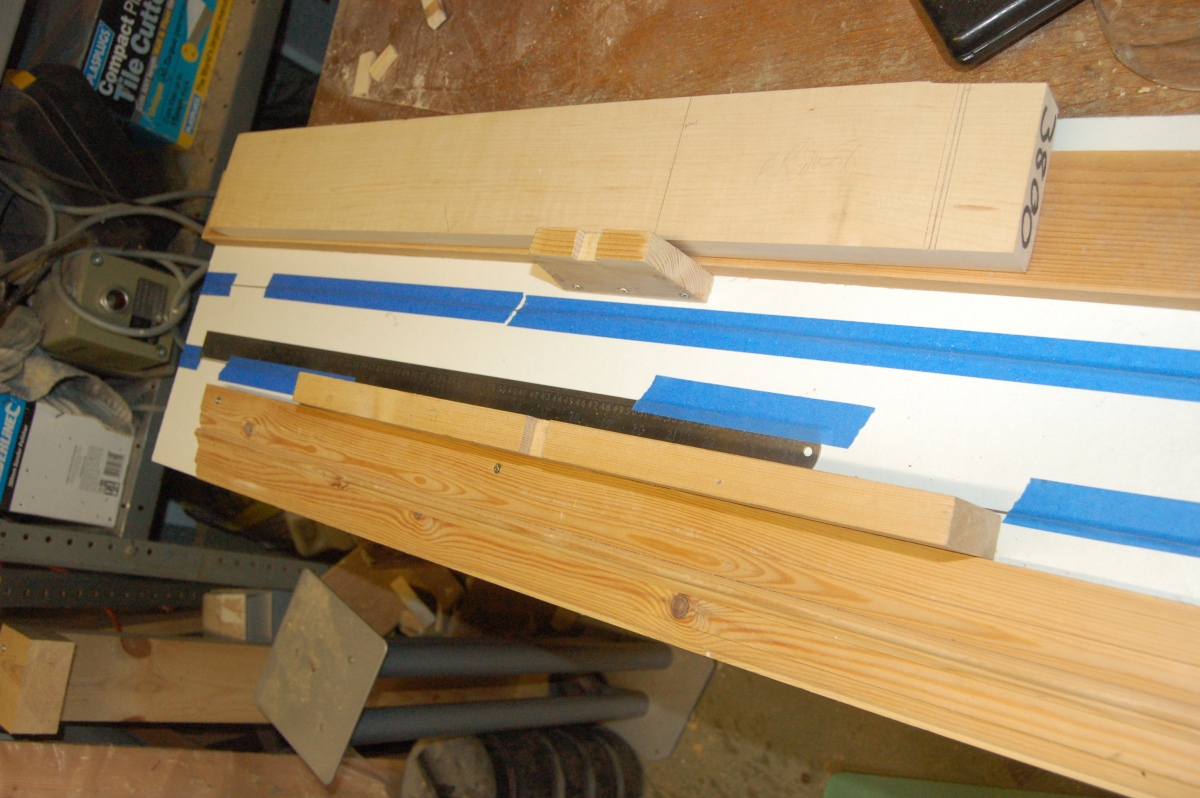

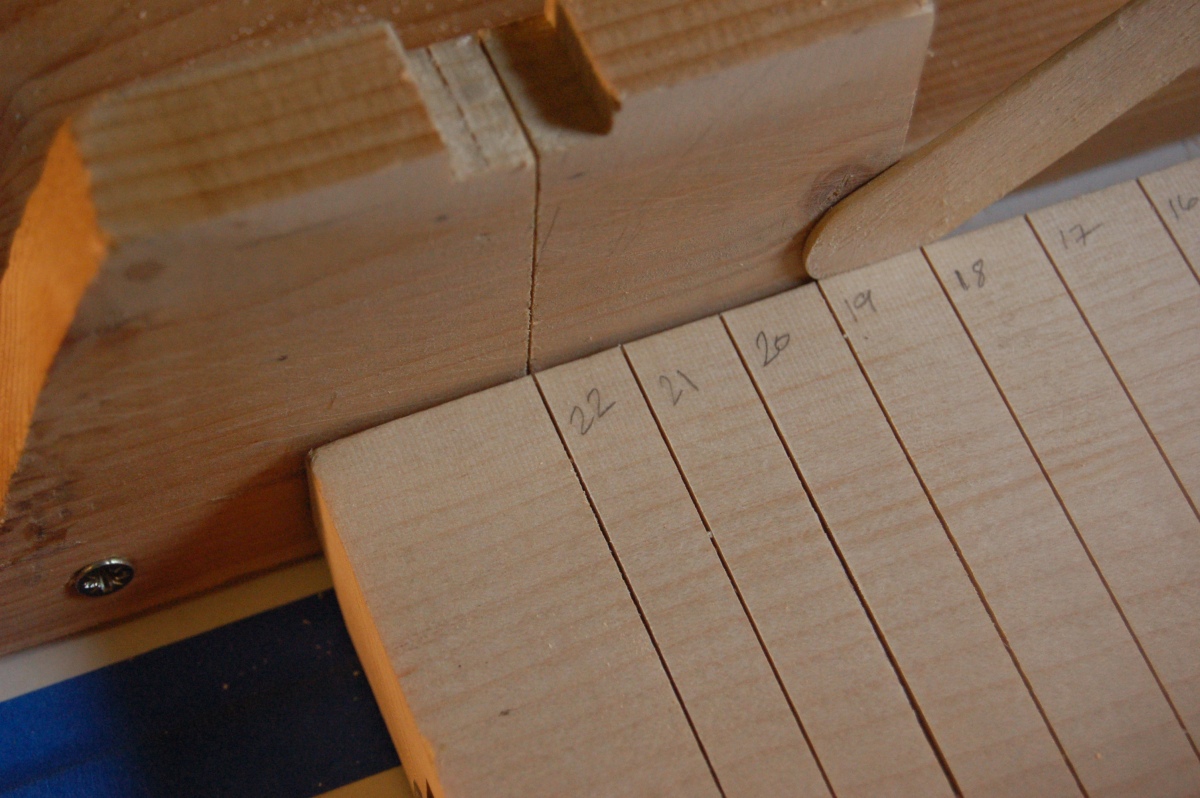

I have a Japanese pull saw (ex B&Q) that seems to be OK for cutting fret slots. I built myself a mitre box to keep the saw square to the neck with a steel rule taped to the base to measure the fret positions.

The chunk missing from the top of the blank is the bit I cut off to repair the wayward truss rod slot, and the cuts in the blank are where I was checking the mitre box was square to the true edge of the neck.

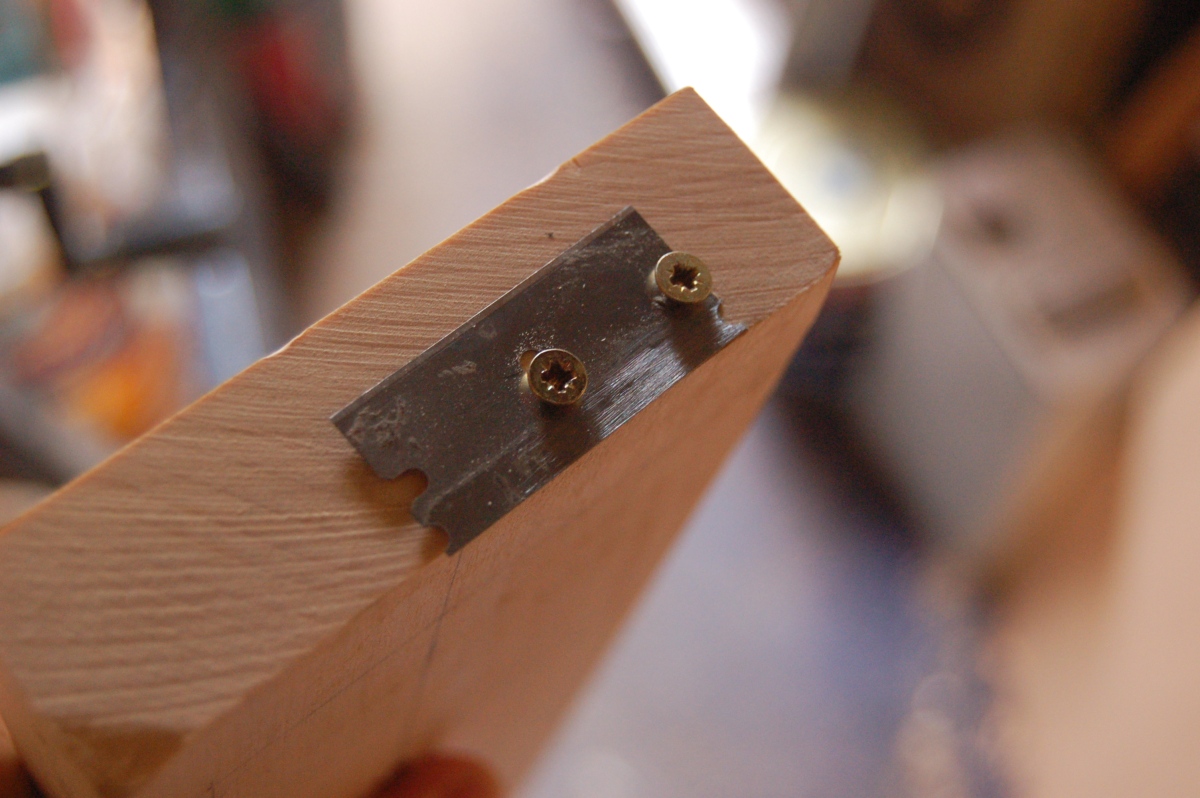

I don’t trust myself to mark measurements accurately, so I fixed a razor blade to the end of the neck and used this as a precise marker against the steel rule to measure the locations for the fret slots. Each time, I also measured the fret-to-fret distance just to double check!

I thought I may as well commit heresy while I was at it:

Once the slots were cut, I could mark out the outline of the neck and saw it roughly to shape: