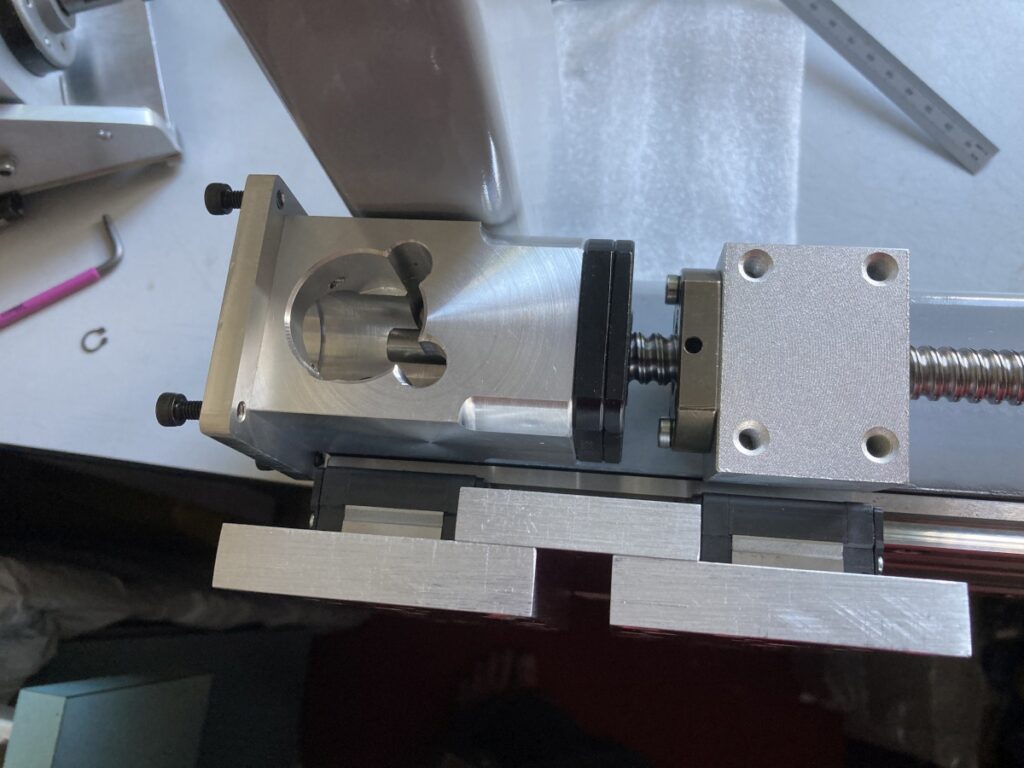

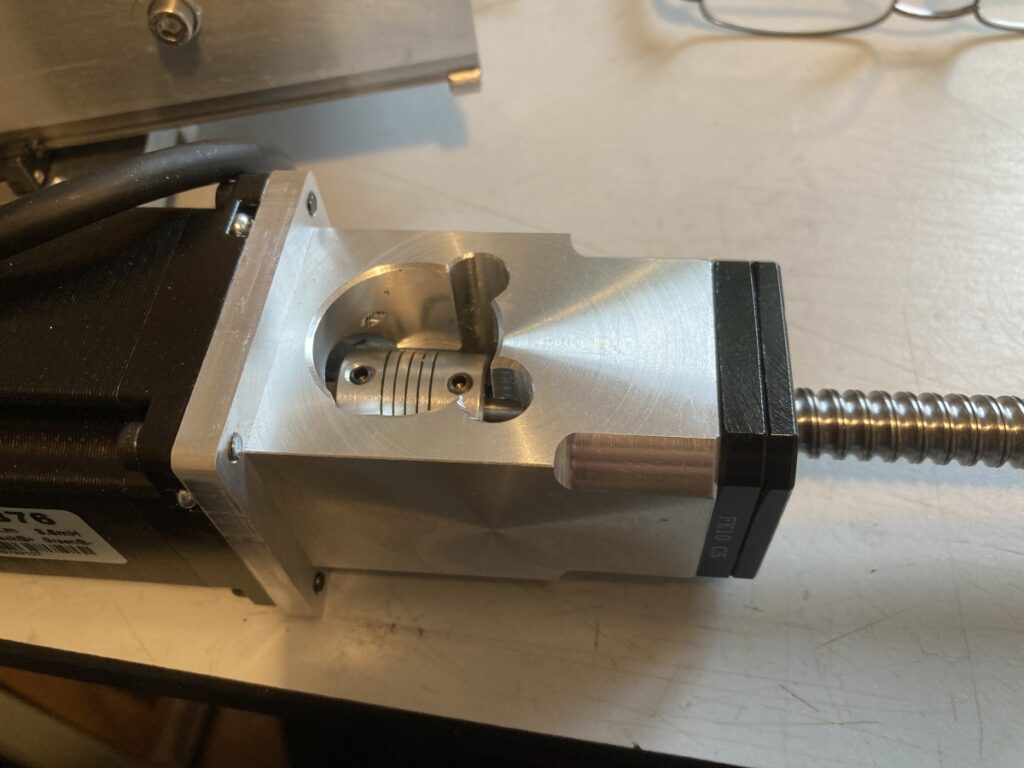

I made up a bracket to hold the X axis stepper motor and leadscrew thrust bearing that would mount to the underside of the gantry – all 4 jaw work on the lathe.

The leadscrew thrust bearing is a standard FK10 from China which came with pukka angular contact bearings in it. The bracket is supposed to be secured with 3 screws into the underside on the gantry.

I thought I was being clever when I welded a block inside the bottom face of the gantry to recieve the screws for the mount when I built the X gantry…

…But I realised that I hadn’t thought this through properly when I marked out where the screw holes needed to be. Some creativity was required to drill them!

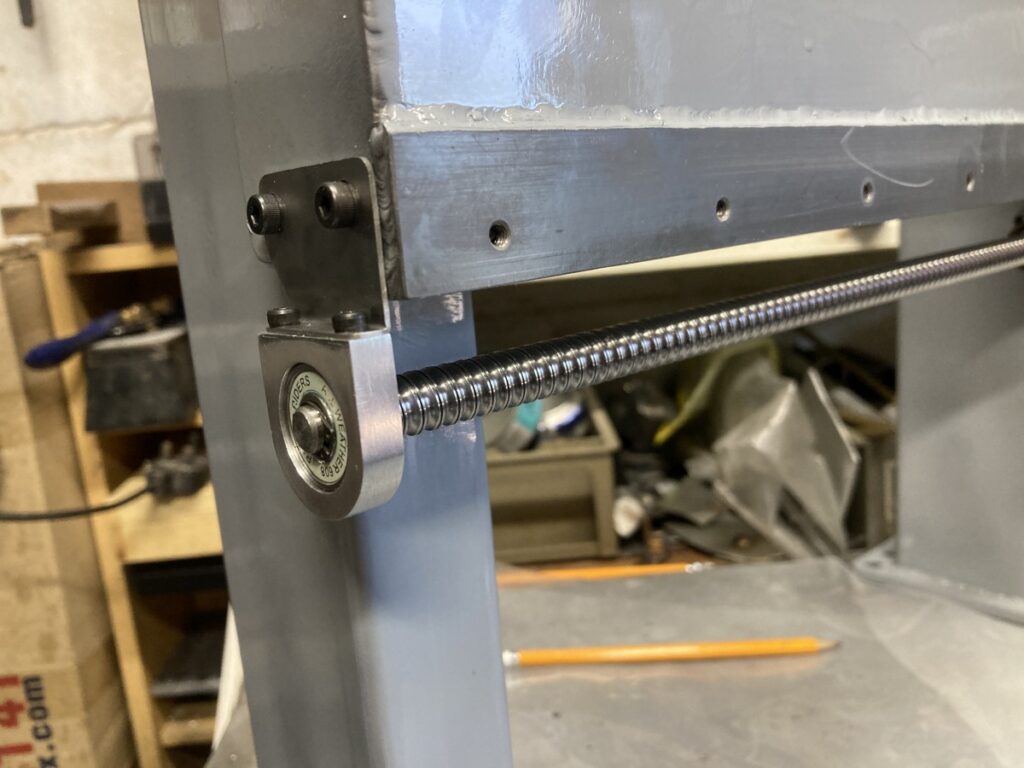

The loose end of the ballscrew is just supported by a normal ball bearing, in a small bracket, to stop it whipping around. This bearing needs to be able to align itself with the leadscrew and offer some leeway in axial position so that it doesn’t over-constrain the leadscrew.

The X axis ball nut housing bolts to a bracket on the X carriage, but needs to be thinned down to clear the gantry legs (easy enough in the 4 jaw chuck on the lathe).