I spent an afternoon playing with my ‘bending iron’. I tried some thin spruce, and it didn’t really want to play, but the offcuts of rosewood bent beautifully, even though they were 2.6mm thick.

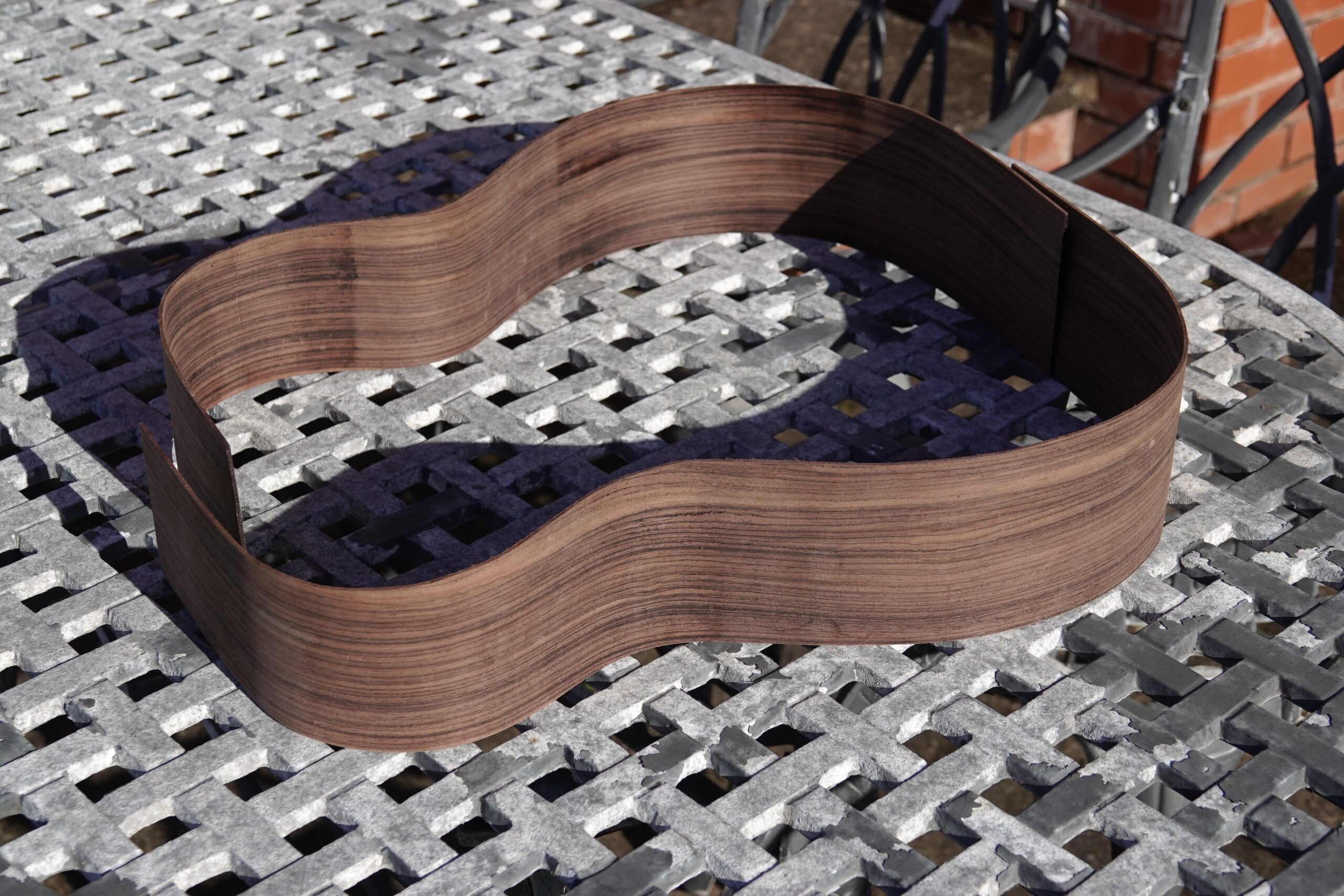

I’d cut some strips from the excess material for the sides and managed to bend a couple of these into fairly convincing guitar shapes. (I had it in the back of my mind that these could well end up being laminated to use as solid linings for the back/side joint. )

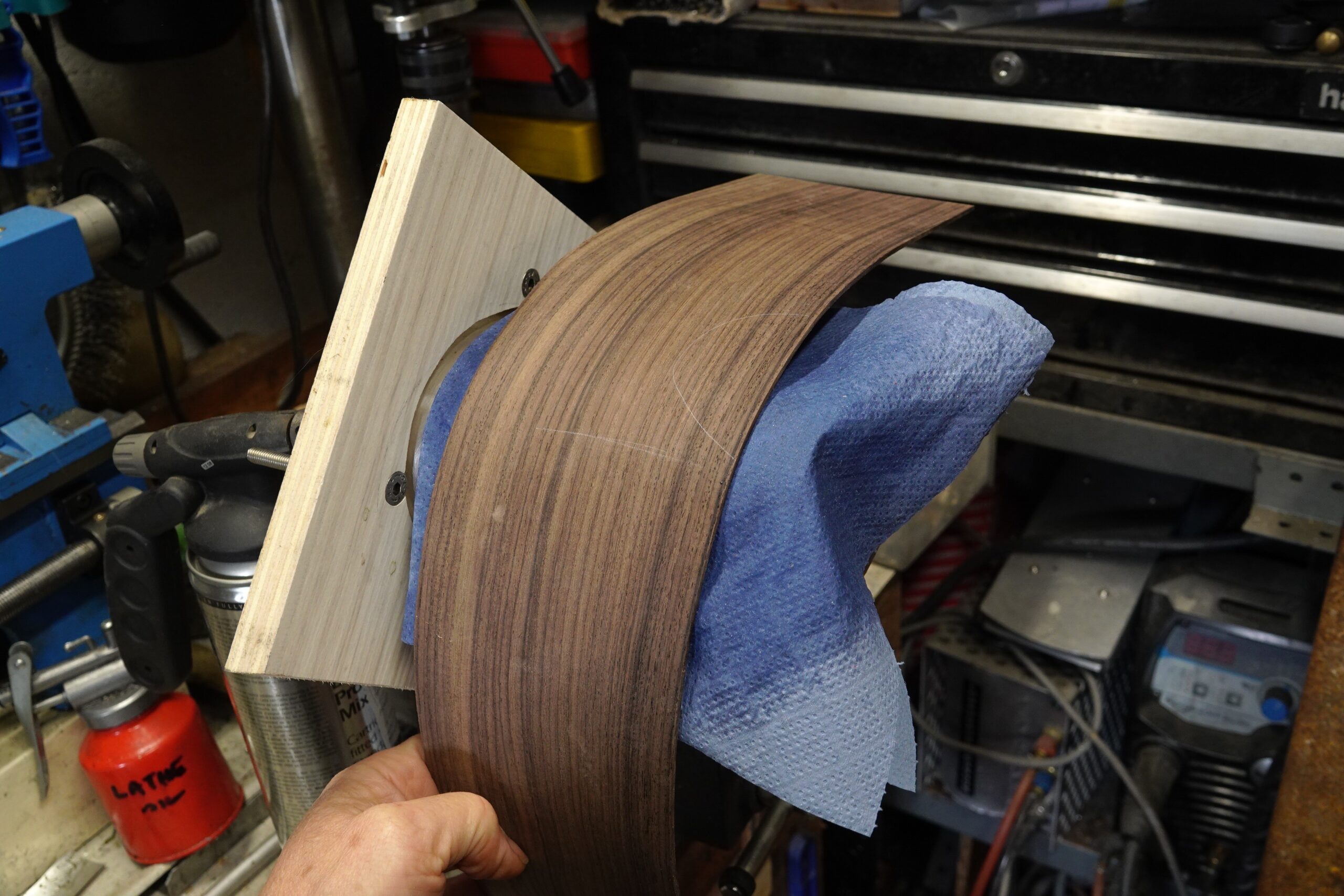

So then, there was nothing for it but to have a go at bending the sides.

I used a damp paper towel between the tube and the wood, and it seemed to go pretty well:

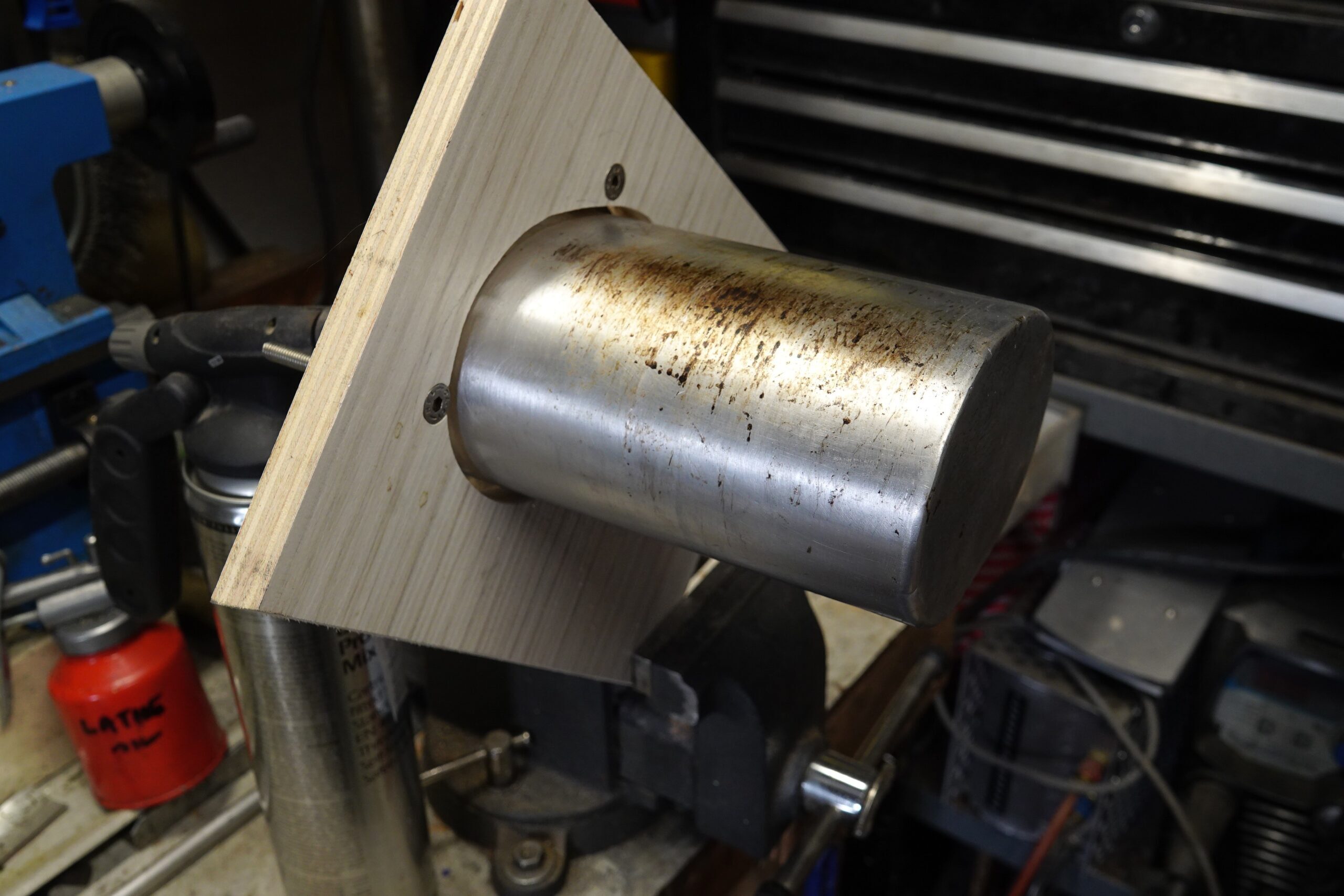

The tube seemed to get plenty hot enough

The clamps are only holding the sides tight to the mould while they dry – there’s no real pressure on them.

Next morning, the sides came out of the mould halves without any spring back at all.

Although the sides looked OK, I could feel a couple of uneven spots when I ran my hand over them. I marked these up – for example there’s a couple of flat spot at one edge of the side here…

… and I spent a little more time back on the bending iron trying to even these out. (I think, sucessfully, but time will tell…)

When I has happy, I put both sides back in the mould to mark and trim the sides to length …

Then glued in the head and tail blocks: