Firstly, I will apologise in advance for being a newbie and heading off piste: I really wanted solid linings in this guitar. I know kerfed linings are traditional and perfectly good, and come from the peones in classical guitar construction, but aesthetically, *I* don’t like them – they always look ‘unfinished’ to me. If it ends up sounding like a banjo, I’ll only have myself to blame!

Early attempts

I had bought some 6mm thick lime wood strips (similar to basswood, I believe) for the linings, and rather naiively set about trying to steam them to shape (they didn’t want to know about bending on the hot tube).

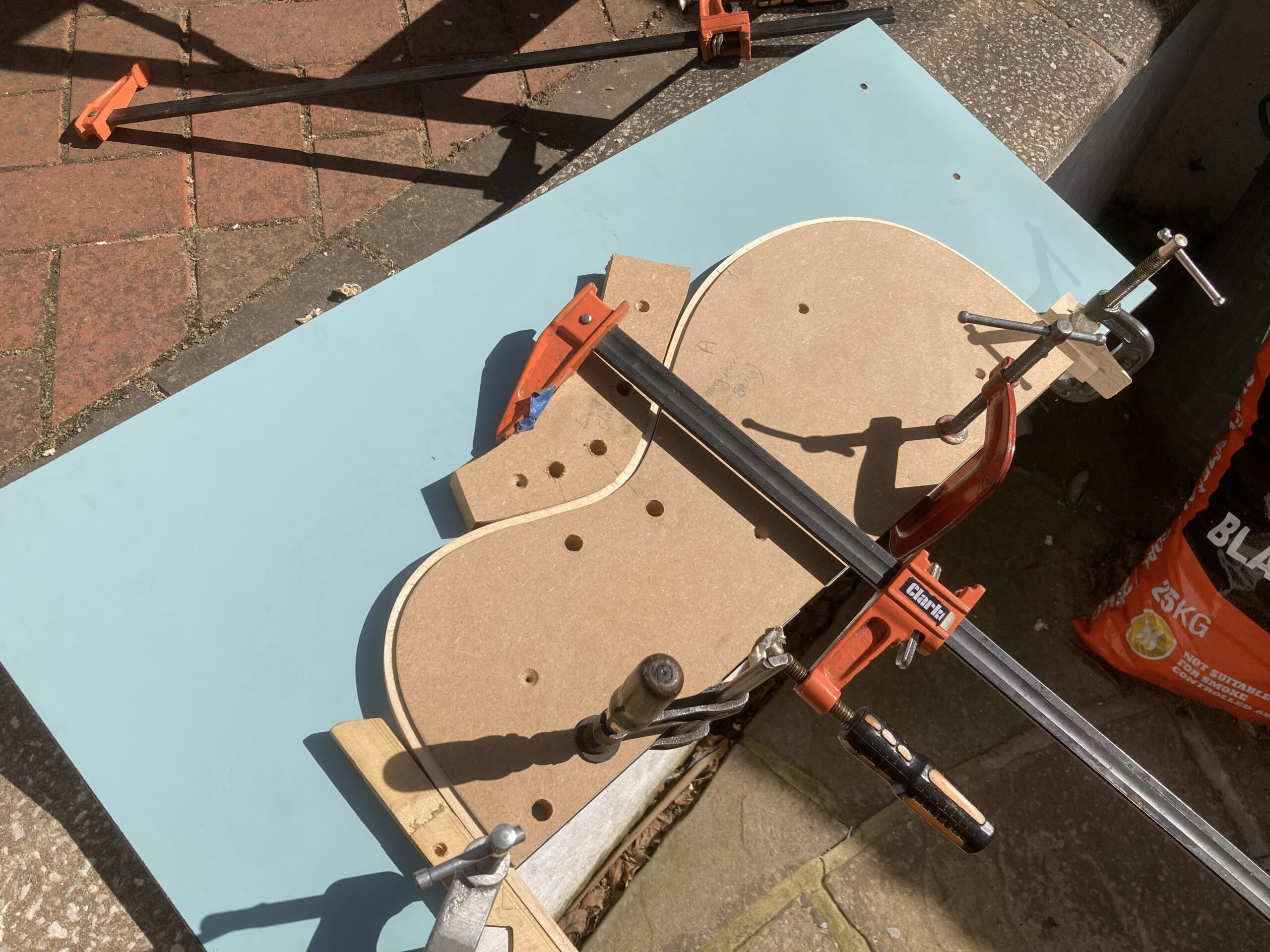

A makeshift steamer, made out of some left over insulation board worked very well in terms of steaming the wood.

I also made a couple of undersized forms to bend the linings around. For my first try, I soaked the strips for 2 days and then steamed them for 30 minutes. They certainly became very pliable, but wouldn’t hold their form when released from the forms a week, or so later.

Also, in the tight curves, they wood developed ugly creases

I had read about basswood wood ‘collapsing’ if over soaked / steamed, so, assuming that lime was similar, I tried again, reducing the strips to 5mm thickness, and steaming them for 15 minutes without any prior soaking.

They at least held (most) of their shape, but were still pretty ugly:

With that out of the way, I decided that the way forward was to laminate the linings (in the manner shown by Beau Hannam’s videos on Youtube).

Laminated Linings

I reduced the strips to 3mm thick using my hand planer on a bench mount (Bosch used to sell a similar adapter – this is my home made version):

These strips bent easily on the hot tube with just a spritz of water…

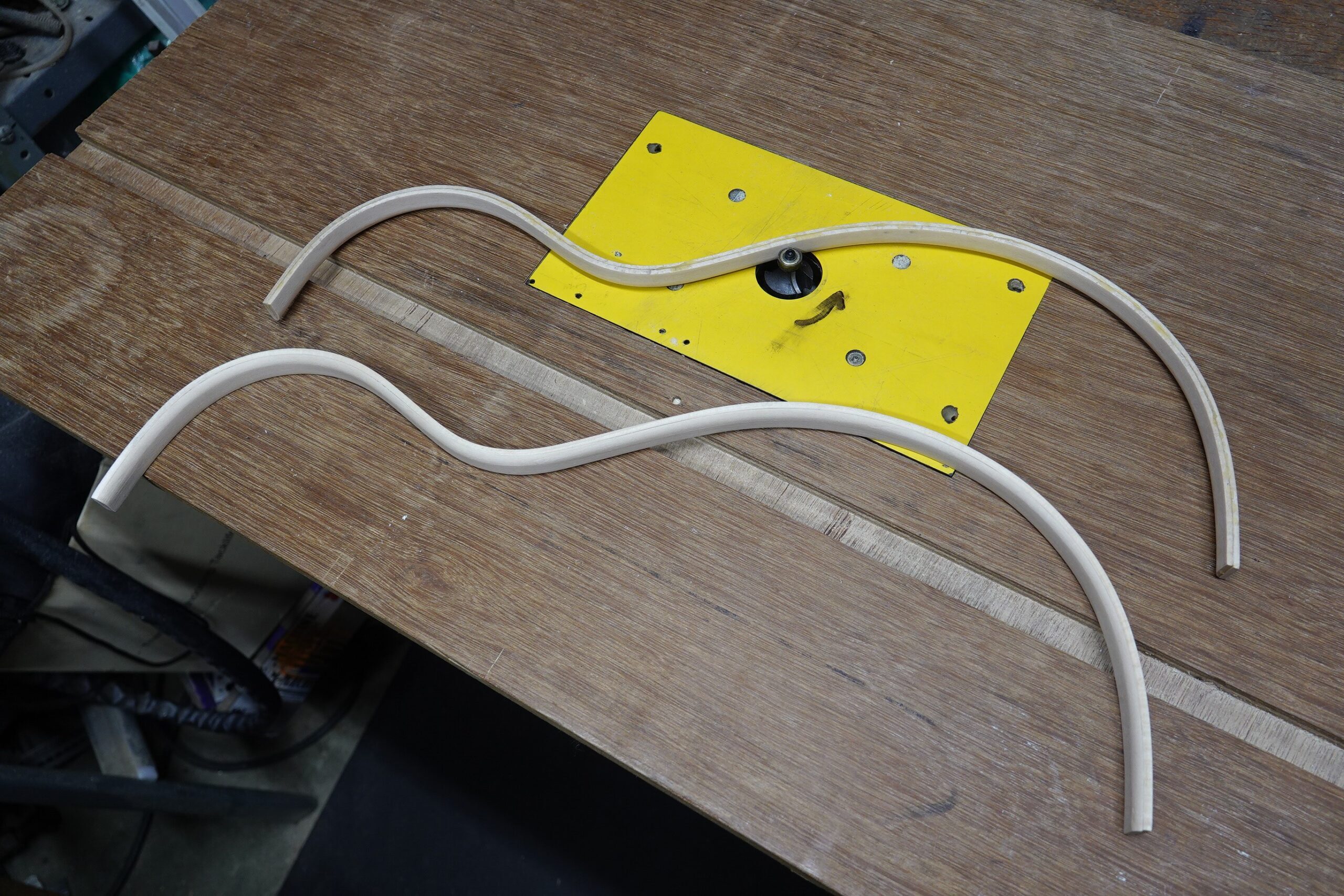

…and held their shape well:

Two strips were laminated in-situ, clamped to the sides

For the back linings, I used strips of rosewood left over from the sides. For reasons even I don’t quite understand, I included a layer of maple veneer in the lamination.

Once the glue had set, I cleaned up the inner edges on my belt sander

And then cut a radius on the inner corner using the router table

Mmm… I like that maple.

Full set of linings

Next job is to sand the inside of the sides and then fit them.