Before having a go at bending the sides, I wanted to make the head and tail blocks. Before I could do that, I wanted to decide on the details of the neck joint. (The plans show a tapered dovetail, but I’m not going to try that.)

Neck attachment options

I would quite like to retain the rather slender heel shape. If I do, I think there needs to be *some* sort of a tenon so that there is enough wood left for strength (otherwise, I was quite attracted by the tenon-less bolt joint). I don’t like the idea of drilling sideways through the tenon for barrel nuts, and I don’t think there’s enough wood there to take a threaded insert (unless I change the heel shape).

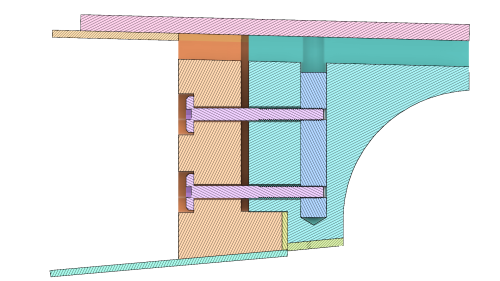

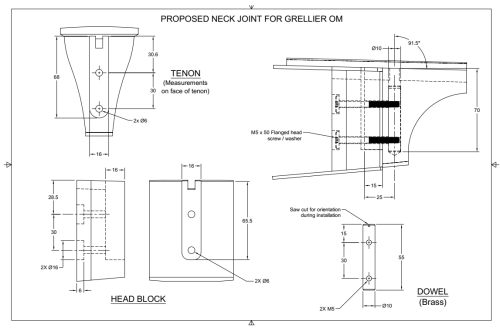

So what I decided to try was a metal dowel set vertically inside the heel through a hole drilled from the top of the neck (the blue bit in the section below):

The tenon is 16mm wide with two M5 bolts threaded into a 10mm diameter brass dowel (dimensions below if anyone is curious – the Grellier plans are available as a DXF file which is fantatically convenient for messing with stuff like this in CAD).

I intend to put belleville washers (they act like short, stiff springs) under the bolt heads to maintain tension as the wood moves with the seasons (this makes sense to me, but I’m not sure if it’s common practice).

Making the head and tail blocks

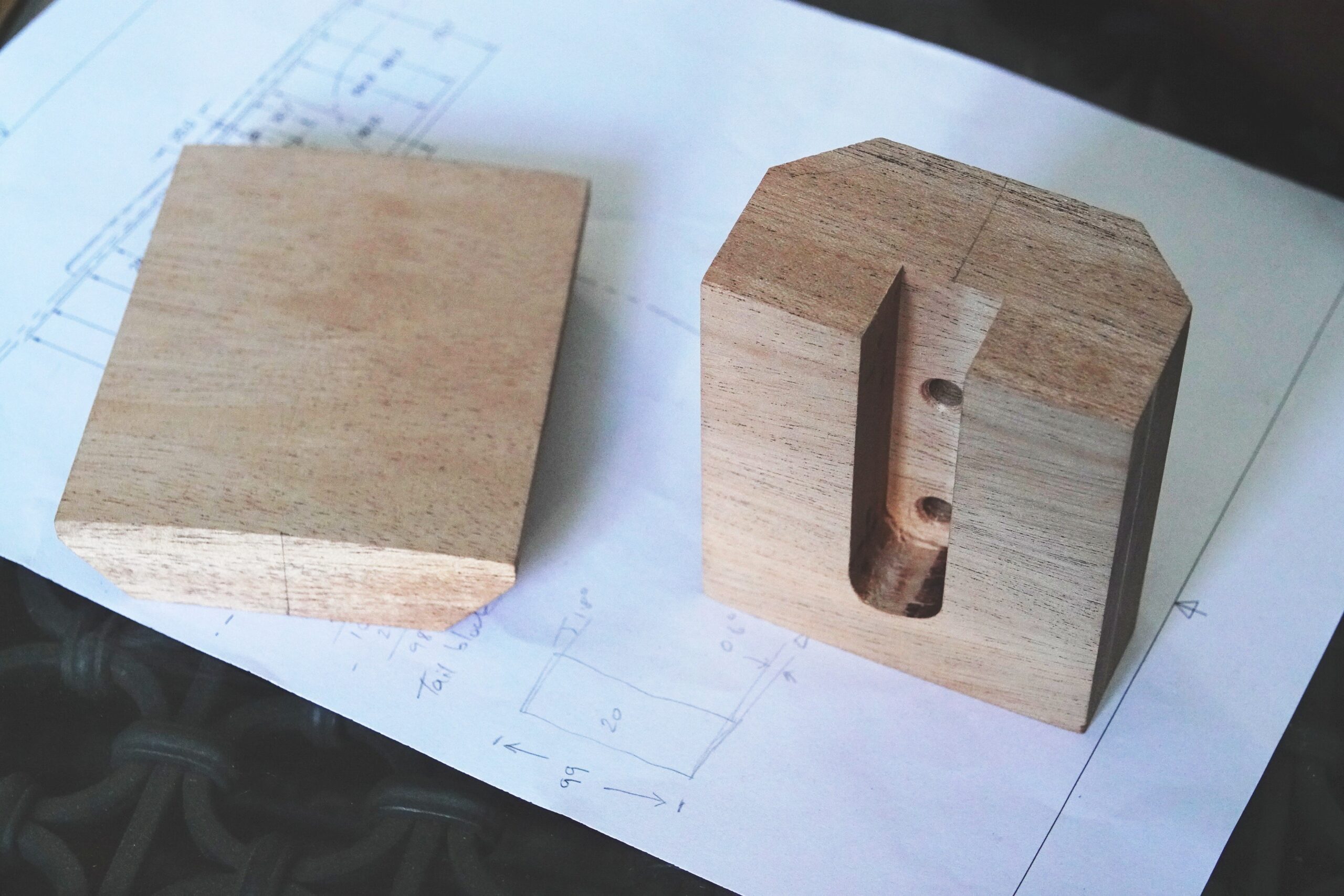

With a plan in mind, at least, I could make the head and tail blocks from the mahogany blanks I’d ordered

I chose to cut the mortice in the head block before fitting it as I fancied my chances of getting it fitted squarely more than I fancied trying to rout it in-situ. If it goes awry, I can fill the mortice and re-cut it, so I won’t be any worse off.

The head and tail blocks were cut to their finished heights (with appropriate angles to match the back and top) and then sanded to match the contour of the mould.

Some modifications to the mould

It had been pointed out to me that the mould I had made was too deep to allow anything to be clamped to the guitar sides, so I exercised my little Delta bandsaw to the max and cut down the mould halves to a more reasonable height.