Preparing the blank

The piece of mahogany for the neck needed to be cut up to make a separate headstock and some blocks to build up the thickness at the heel. I trimmed the end of the blank to something like the finished neck thickness to make before gluing the scarf joint so that subsequent carving would be easier.

…and added a stack of blocks for the heel:

After cleaning it up a bit:

Fixing Bolts

I had ordered some threaded inserts to see how they would pan out for the neck attachment, but despite them being described as steel (two separate suppliers), when they turned up both lots were some sort of cast zinc. I was concerned that the threads might get chewed up easily (I’ve damaged enough of them over the years) so I decided to stick with my plan to use a vertical dowel.

I needed to drill the hole for the dowel before routing the truss rod slot (because they intersect) but, in hindsight, it would have been better to delay drilling the screw holes until I could put the neck in position and mark through from the headblock. (Yeah, I know one of them is wonky, but it’s oversized and still pointing close enough to the right direction…)

Cutting the Neck Tenon

I went around in circles trying to think of a clever way to cut the tenon (router, sliding mitre saw, etc.) but in the end I just used a dovetail saw for the shoulder cuts and the bandsaw for the cheek cuts.

I aimed to angle the shoulders in slightly per the Cumpiano book.

One side is cleaner than the other – I guess I can put whatever time it would have taken me to build a router jig into finessing the hand cut joint. Time will tell…

Headstock

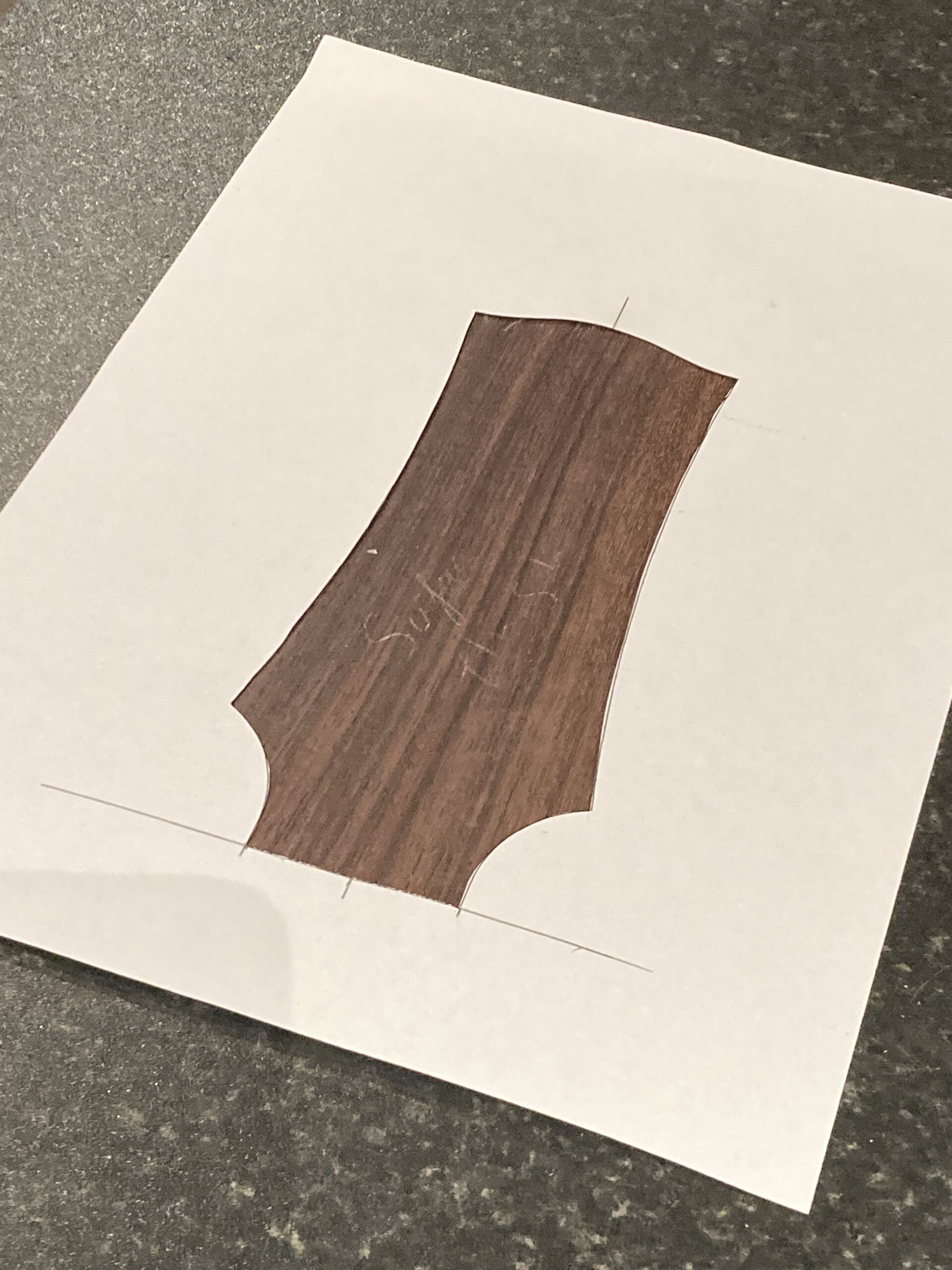

I wasn’t keen on the headstock outline in the Grellier drawing, so doodled around and came up with something I was happier with that gave a slightly better string angle to the tuners. I cut the shape out of paper and laid it onto the headplate blank to see if it would look OK, and to choose where on the blank to cut it from. Looked OK to me on the rosewood blank.

So I cheated and used my little CNC router to make a routing / drilling template out of 3mm ply

(There are a couple of sets of holes on the treble side as I was still toying with an asymmetric layout.)

I bandsawed a quick-and-dirty dummy headstock out of a piece of scrap 12mm ply to see how the tuning machines fitted and to check for clearance:

The symmetrical arrangement seemed to fit fine and looked OK to me – Decision made.