I’ve had a long-standing hankering to build a steel strung acoustic, and approaching Autumn 2023, this escalated to a burning desire.

After quite a lot of reading (both on the ‘net and in real books), I thought I understood the build process, but was still learning. I had hand tools and a router, etc. but no thickness sander or planer, so would probably order the back / sides & soundboard already thickness sanded.

When I was looking for plans, I came across the drawings on C. Grellier’s website – in particular the OM: (link to pdf) which seemed to fit the bill. The plans are well drawn and seem to be self-consistent. A quick trip to the print shop got a couple of copies printed at A0 – the dimensions came out spot-on.

More significantly, I ordered some wood, expecting it to take a few weeks. It appeared within a couple of days.

Nothing exotic or unconventional: German spruce top, Indian rosewood back and side set, and a mahogany neck from Keystone; and an ebony fingerboard, rosewood bridge and miscellaneous bits of binding, lining and purfling from David Dyke.

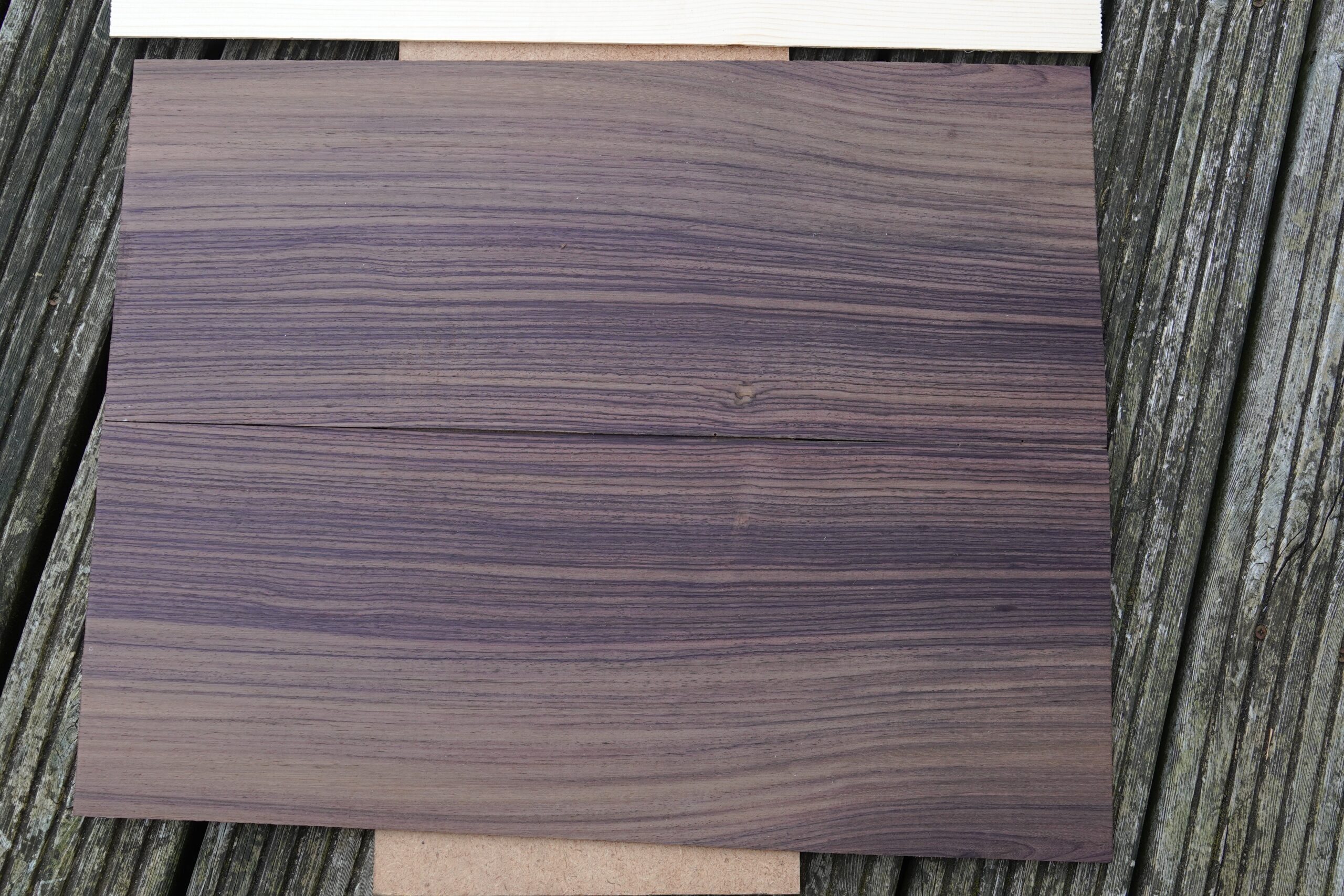

The back, sides and top had all been thickness sanded before despatch. All the wood was the lowest grade on offer, as I didn’t want to butcher anything fancy, but despite that, the sides looked beautiful:

The back had some worm holes near the join line that needed to be sawn off; a bit of a knot / whorl going on and some residual saw marks – the plates were already down to 2.6/2.7mm thick so there would only be a little bit of material to take off to get to the 2.5mm on the plan.

The European spruce top was generally lovely and looked very well quarter sawn. The outlines drawn on the wood were from the supplier, and are a bit bigger than the OM, but even so, I don’t think I’ll be able to avoid the dark grain lines at the edges of the lower bout.

Not knowing what else to do with it, I just stacked it all back together on the backer boards used for posting, wrapped it loosely and put it in a spare bedroom.

As a bit of a displacement activity, I traced a template from the plan and used it to make an external mould out of MDF. I’d forgotten how much I hated MDF.

It would be a few weeks before I plucked up the courage to try and do anything with it.

(Incidentally, don’t make your mould this deep – 3 layers of 18mm MDF are plenty)