Hello again!

Well, after a bit of a hiatus, I got back to this project and assembled the various bits and bobs I needed to try running it on liquid fuel.

The main requirement is a a pump capable of providing a controllable flow of fuel that can be adjusted from a bare dribble with no delivery pressure to ~ 250cc / minute against ~1 bar back pressure from the engine. The proper pumps are ruinously expensive (~£300+) so I am trying a cheap RC Glow fuel transfer pump:

It is a positive displacement gear pump (I had to open it as it wouldn’t run when I got it – there was a bit of plastic flash stuck in the works)

I was thinking of running it with a pressure relief valve and controlling the fuel flow with a needle valve, but as it transpires, there’s so much back-leakage in the pump that it will run against a dead head without complaining too much, so I just used a cheap (and very nasty) Chinese needle valve to shut the fuel off and control the initial flow:

A portion of the fuel feed is diverted to lubricate the bearings (it has oil mixed into it for this purpose). The flow to the bearings is restricted by a fine hypodermic needle (0.4mm bore). To try and stop it blocking, I added a fine filter to the line before it.

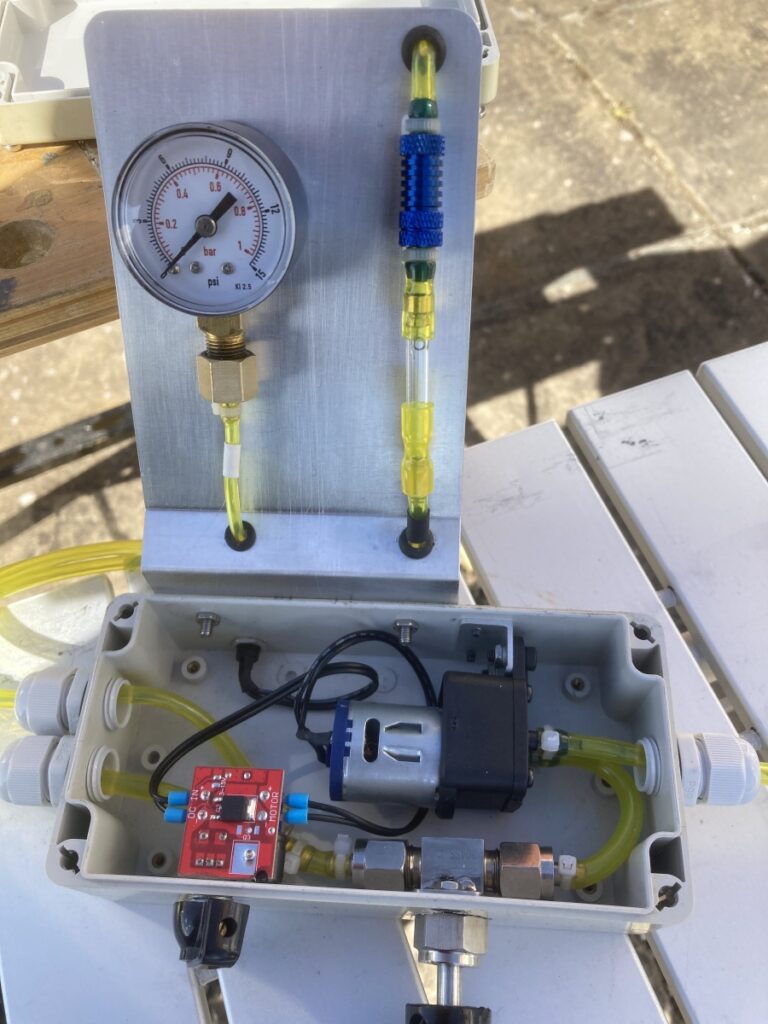

After faffing about trying to make a neat looking arrangement, I eventually gave up and threw the lot in a old box that I had knocking about:

The fine filter is the blue thing on the right, and the needle for the lube restrictor is coiled up inside the glass tube which is there to (hopefully) provide some sort of tell-tale for the lubrication flow. The lubrication restrictor in as per the book (0.6mm OD/0.4mm ID x 25mm – book says 30mm IIRC) hypodermic needle – Poiseuille’s law says that when compared with 6 off, 0.6mm ID x 50mm long needles, it will take ~1% of the flow. (Seems low to me, but my maths might be wrong. I’ll go with the book, anyway).

The pressure gauge measures the pressure being developed inside the engine casing (this was a convenient place to put it).

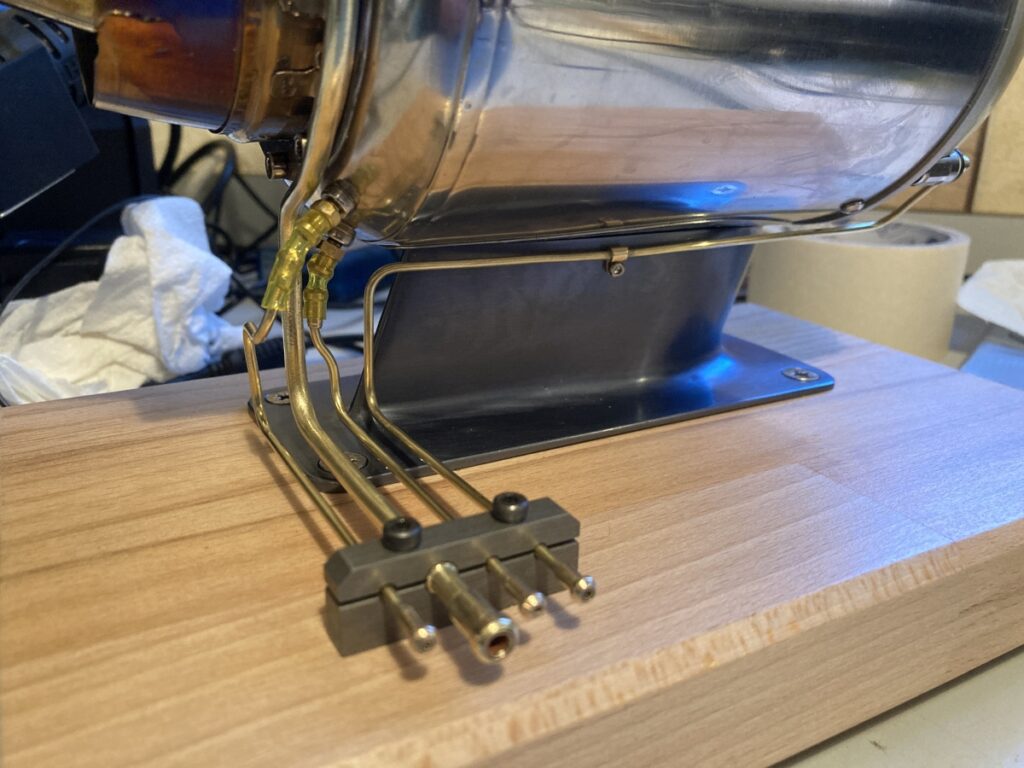

I consoled myself with making some shiny pipes to fit on the engine instead:

And a bulkhead fitting…

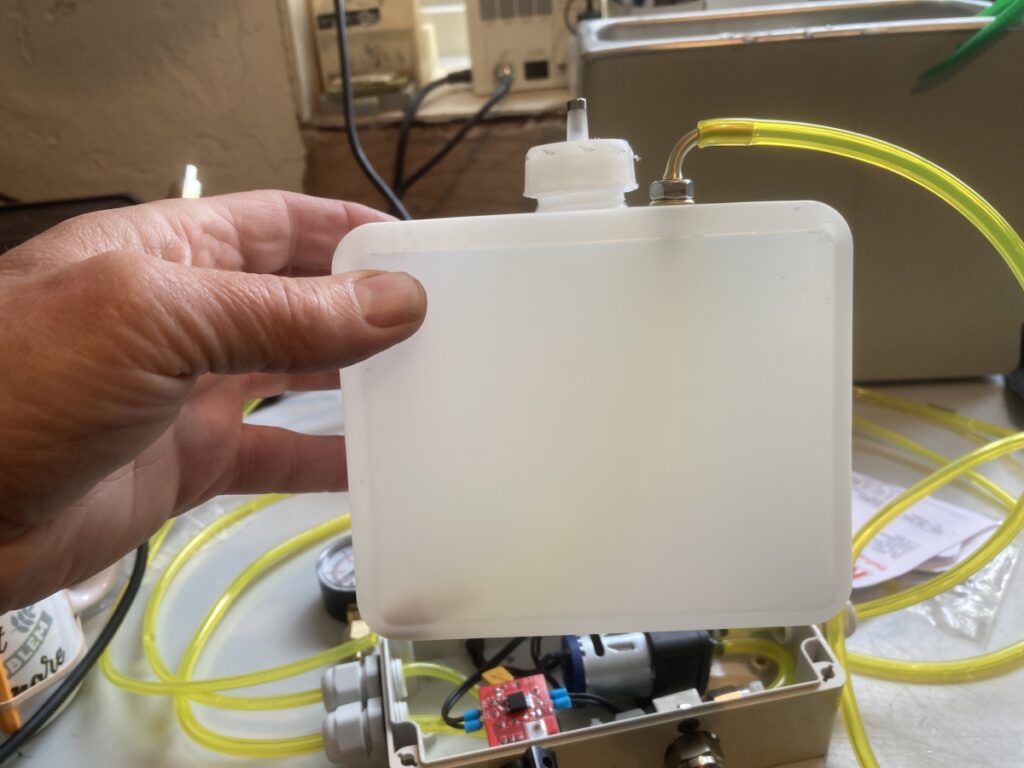

…for the fuel tank (made from an old battery acid container)

It all came together quite nicely:

And there were no more excuses for not trying it out.

The fuel is domestic heating oil (28sec kerosene) mixed with 4% TWC-3 two stroke oil.

It’s necessary to run the engine up on gas for a short time to pre-heat it so that when the liquid fuel is introduced, it will vaporise straight away. The rather dramatic thumbnail for the video is just the starting gas igniting with a bit of a ‘wumpf’.

The pump ran out of oomph at 0.6 bar engine pressure running off an 8.4V pack, but I think it will be OK on 12V

I couldn’t get an RPM reading with my [cheap] optical tacho which made me nervous of pushing the engine too far.

I’m also putting my hands too close to the inlet still. It gives a false sense of security when it’s running on idle. (It nearly swallowed the tacho at 7:30!)

Overall, very pleased with how it went – the engine ran very sweetly and was very tractable. I was reluctant to push it without knowing what speed it was doing. (I think my turbine wheel should be OK to ~98,000 RPM, but ultimately, these engines have no rev limit – short of self destruction.) As it happens, I was limited by the pump in this case, but a few more volts will overcome that (I was running a 12V pump off 8.4V).

I want to sort out a reliable means of measuring RPM, then I can mount the engine on some sort of rails and see if is produces thrust or just noise and smoke.