The book recommends turning the threads off the diffuser securing screws where they pass through the diffuser air passages and fairing them in with epoxy (so that they don’t interfere with the airflow).

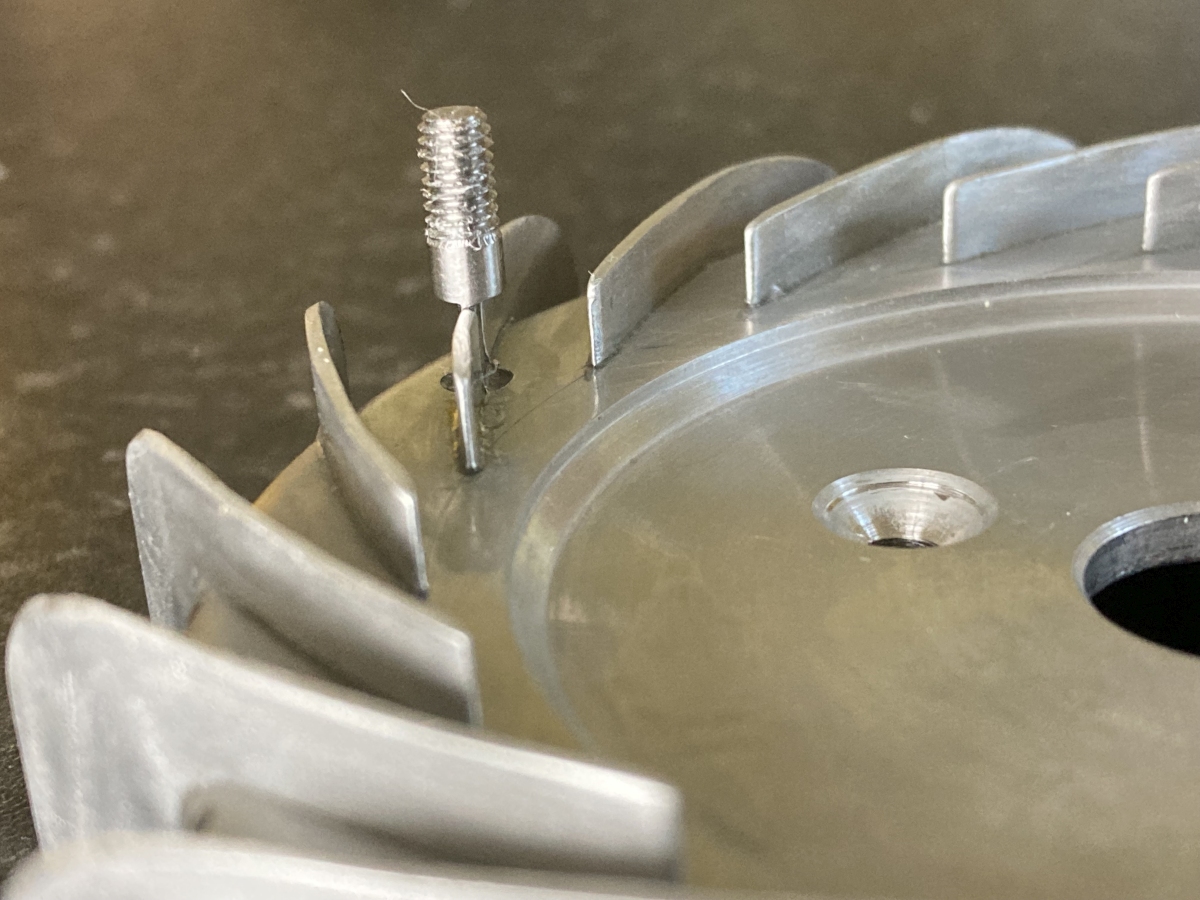

I reckoned I could get a stronger result, with less disturbance of the airflow by making some flatted studs instead.

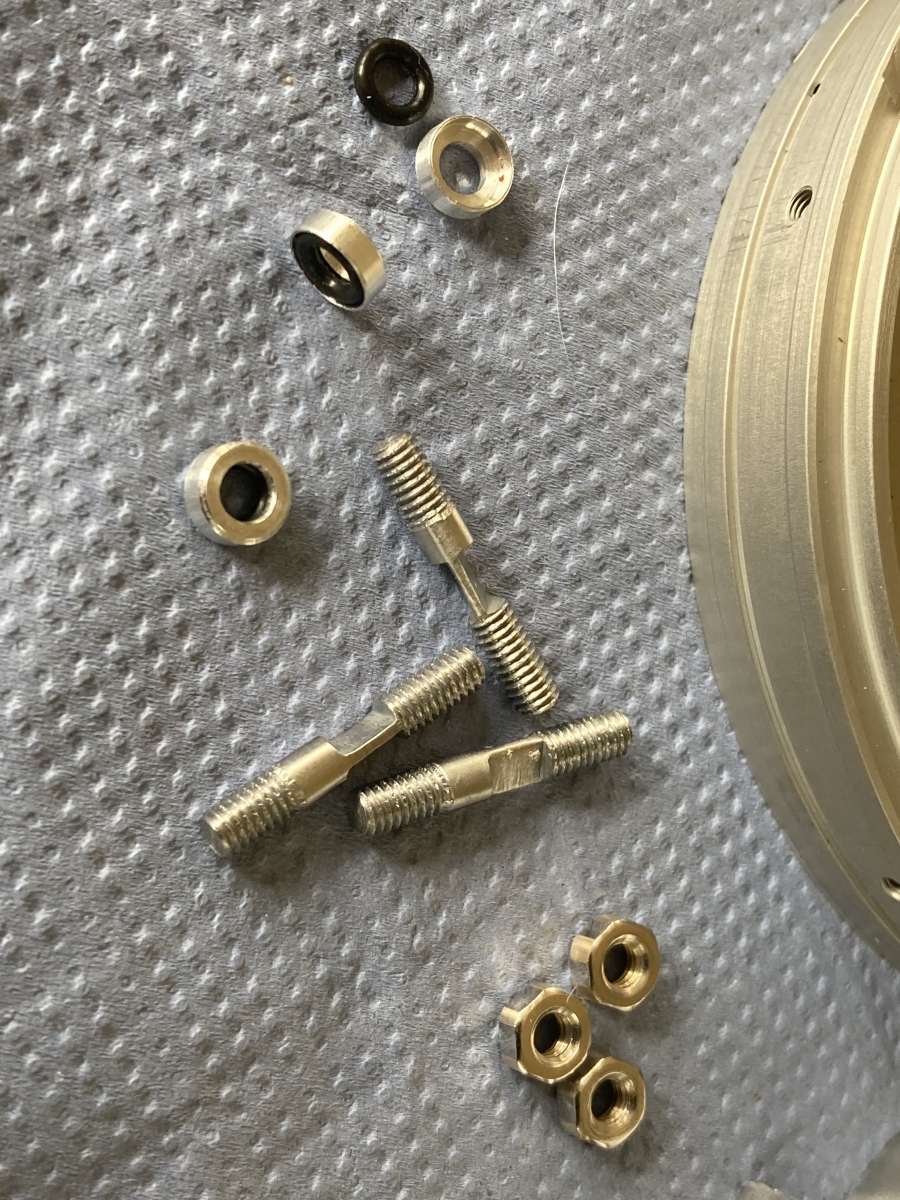

I made the studs out of silver steel and locked each one into a plate in the tool holder on the lathe to mill a 5mm tall flat on opposing sides. (I flipped the piece of steel around in the tool holder to get the opposite side).

Making the studs this way also meant I could leave a plain section where they pass through the front cover. To try and seal the hole properly I made some small stand-offs with an o-ring in the end that *should* seal against the stud and front cover.

The studs were screwed into the diffuser body and held in place by a locknut behind the diffuser. Once I was happy with the fit of things, they were removed and re-fitted permanently with epoxy.

I’m pretty pleased with the way that worked.

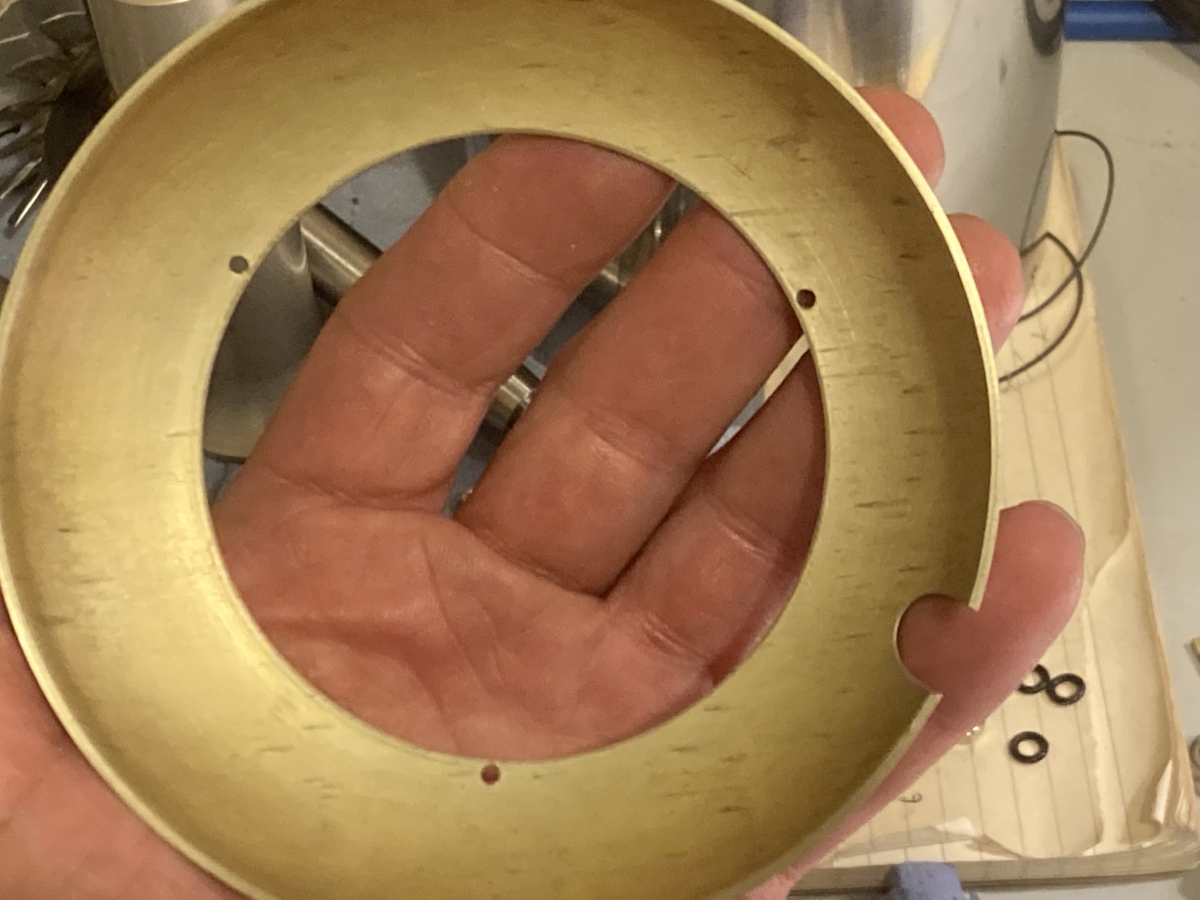

I also anodised the aluminium components:

I gave the fairing a little colour, as the 1050 sheet it’s made of comes out quite grey compared to the 6XXX of the machined parts.

(I got some weird streaking on the inside of the fairing, I think related to the grain in the raw sheet. I don’t know what’s caused this, but luckily it’s much more feint on the outer surface which has been smoothed and sanded.)

Getting there!